I just unwrapped a cable that's been sitting in the closet for a year. I was checking fit. I discovered it has the exact same magic crimp terminals I never knew about until like a month ago, which shows how much attention I've been paying to that stuff. it was sitting on top of a $15k box of servo amps that have mostly been taking up space. I grabbed it, put it in a raceway i designed, and said, aloud, "this is going to fucking rule." This little fucker is gonna be packed like a goddamn fighter plane. And from every indication I have, it's going to work. Not that I can even explain it. Most of the people around me don't even know what a CNC machine is, let alone know they can be built. That 400-piece black brick is mostly cable management surrounding six servos. It's all bolted to a cutting board because it's cheaper buying Delrin slabs as "cutting boards" from Amazon than it is to get the material from an industrial supplier. I know one guy who reacts with a "holy shit" because he knows what he's looking at. I guess that should count for more because he uses these tools for a living. The fact that nobody else even has the vocab to figure out what I've been struggling with is pretty goddamn frustrating tho. In my head I've been building legos for a year and I can't get the goddamn spaceship canopy on. I forget that most people don't view legos conceptually as something you can make from nothing. if you change the hole spacing to 12.9mm the assembly is modular I just finished Ed Niedermeyer's Ludicrous, which is basically "Tesla is a piece of shit, let me count the ways." I have an engineering degree and it's the first time I've heard of tolerance stacking as a concept, which is pretty much shame on my alma mater 'cuz it explains a lot. Like why Teslas are pieces of shit with fit and finish that would embarrass Tatra. This fucking thing was welded with a harbor freight mig welder on my cousin's garage floor with vice grips for jigging. No proto. No dry run. Dimensional transfer through printing to an Epson inkjet, then cutting out profiles with an X-acto knife, then rubber-cementing the paper dolls to the metal, then using a hand punch and a ball peen hammer to mark centers, then holes drilled with a donor 40-year-old nameless Chinese drill press. You know what? Of the 896 parts on this cart? THREE screws didn't line up. Fuck you, Elon Musk. Fuck you, tech industry. Fuck you, dad. I'm actually pretty fucking goddamn good at this shit.

The work you are doing reminds me of my early days in the Silicon Valley tech industry... we'd dumpster dive behind various tech companies (like DEC, or Apple, or SGI) and find old hardware like your drill press... and then have to figure out how to make it work, all with nothing but voltmeters, oscilloscopes, and catalogs of microprocessor chips that showed processor pinouts. (No internet, back then.) We'd jury-rig the equipment to do whatever we needed it to do, build shit, and sell products. Product development was only limited by how creative we could be with the stuff we salvaged or got second-hand with no manuals or cables... I loved digging in, figuring out how some device worked, then trying to make it work differently to do whatever we needed it to do to work on our "production line". (Which mostly consisted of Henry, the EE, telling me what to do with the soldering iron before surface-mount tech took over.) I can appreciate the personal thrills and fun you are having as you make these things work with elegant, hand-engineered solutions... but it is so far outside of my depth by now, that I can only view the waves as they crash on the beach, without understanding what is making the water move. Still... I find all of your updates fascinating!

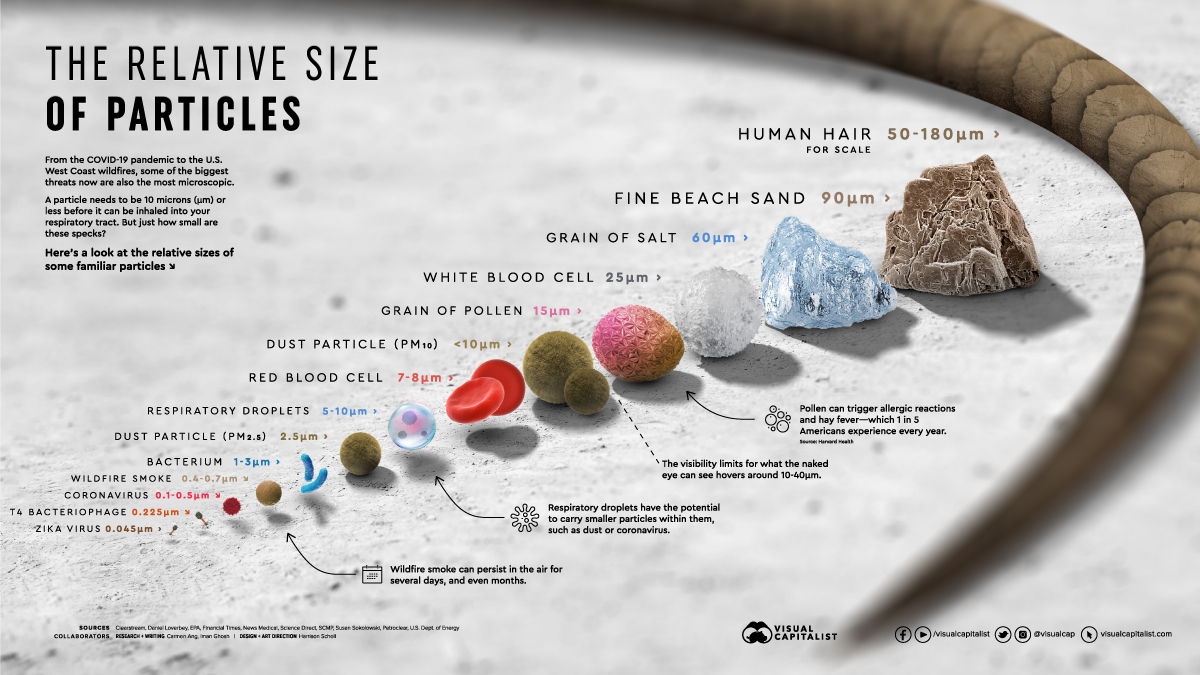

Spindle stories The spindle is the spinny thing you attach tools to. "runout" is how much it wiggles in its orbit while it does so. This particular spindle company is known for unreal precision and runouts to a tenth of a micron. Mine requires four kinds of air. I had no information on it. Fortunately the company that made mine had recently refurbished one (sequentially, the serial number after mine) for Patek Philippe, so they had specs. Those specs were transliterated poorly, so a friend who makes parts for Arnold & Son was able to help me. I inquired as to what it would cost to get said spindle rebuilt, because it probably needed it (the prior owner had savaged the encoder cables off below the nut, and who knows what else). I was informed that their overhaul was "around $18-20k" and they gave me the name of a company in NC who could do it faster for less. I have 85 pictures of the horrorshow that is my spindle. They gave me a quote of $7k, and then didn't bat an eye when I asked if they could increase their tolerances by an order of magnitude to match factory spec. Mathematically, which means assuming no ball screw backlash which is nonsense, the precision in X, Y and Z will be half a micron. It will be more than that because there is ball screw backlash. However, with the addition of closed-loop modules for the servo packs ($300 ea) and absolute encoders ($X - under research), the absolute precision of the X, Y and Z can be reduced to 0.01 microns. That's 10 nanometers, or the difference between orangey-yellow and yellowy-orange. Theory and practice are two totally different things, but in theory it's gonna be sumpin'.